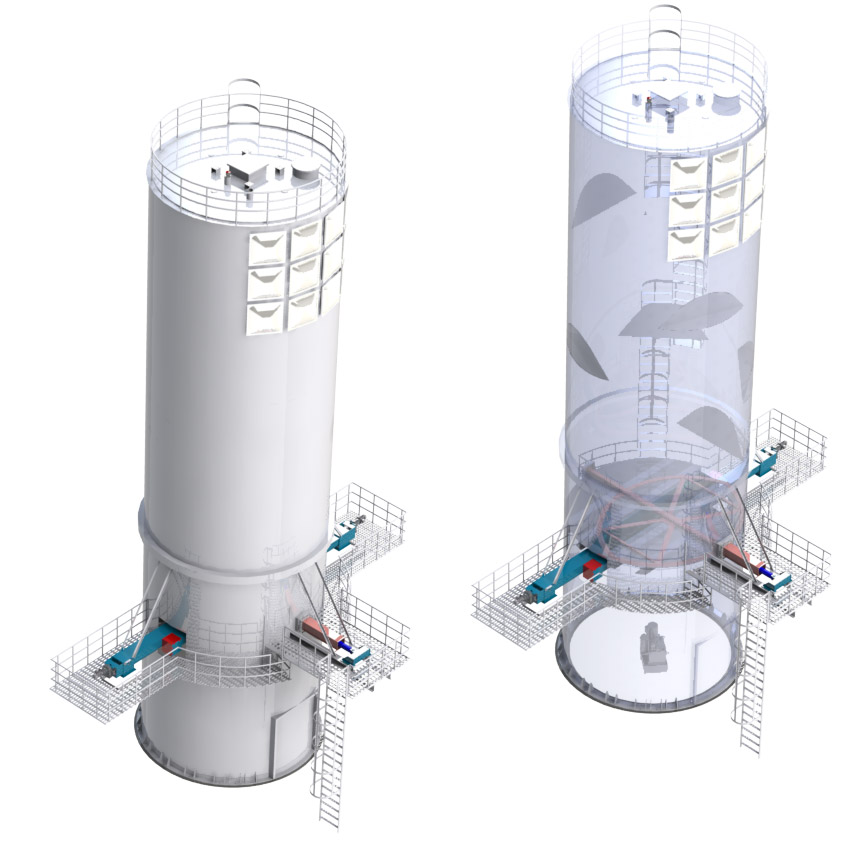

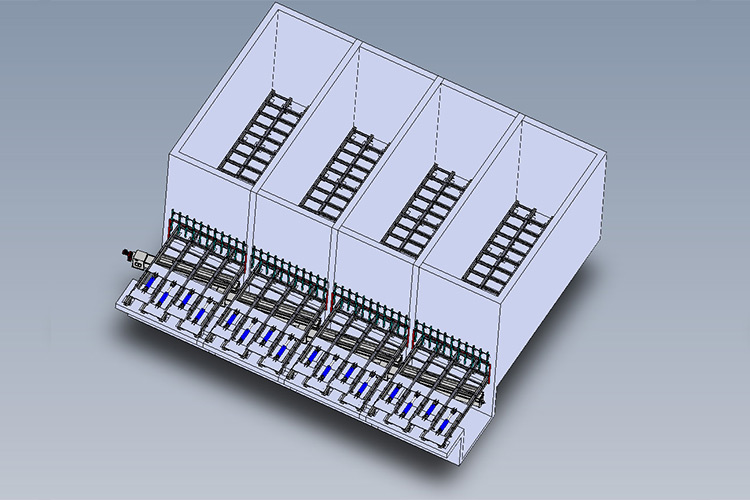

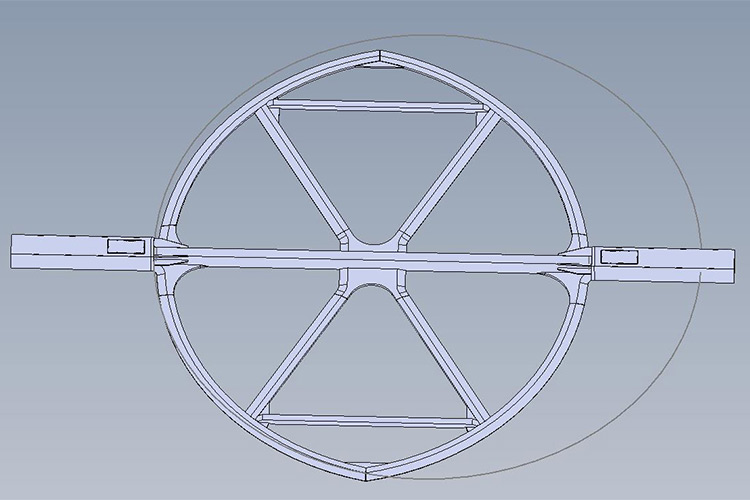

Two truck loading silos for sewage sludge

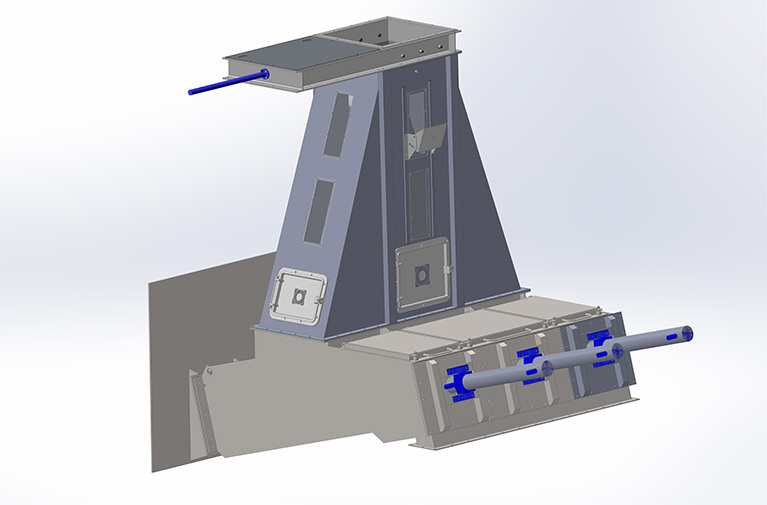

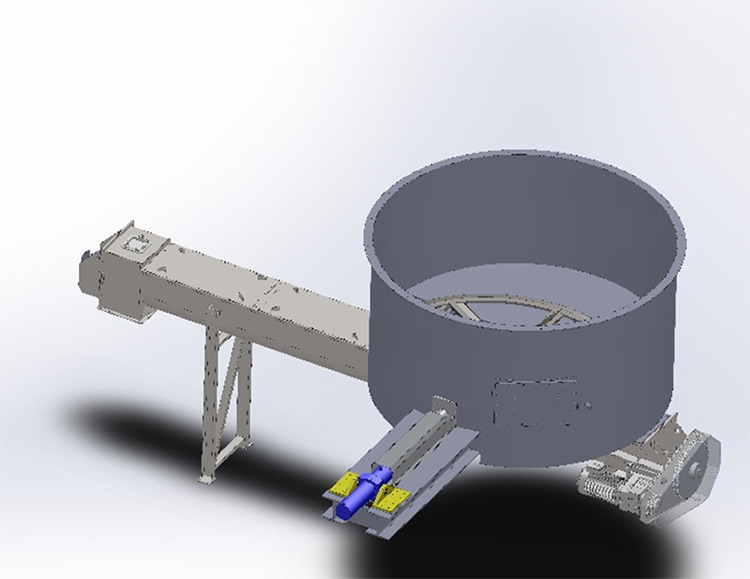

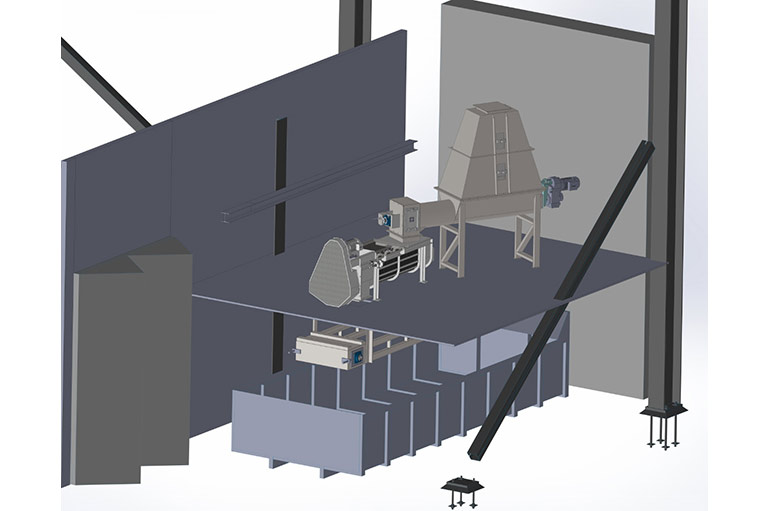

Discharge System for sewage sludge loading station Saxwerk receives the order to supply and install two discharge systems for a sewage sludge loading station at a sewage treatment plant in southern Germany. The sewage sludge loading station is used for the intermediate storage and truck loading of mechanically dewatered sewage sludge at a municipal sewage [...]