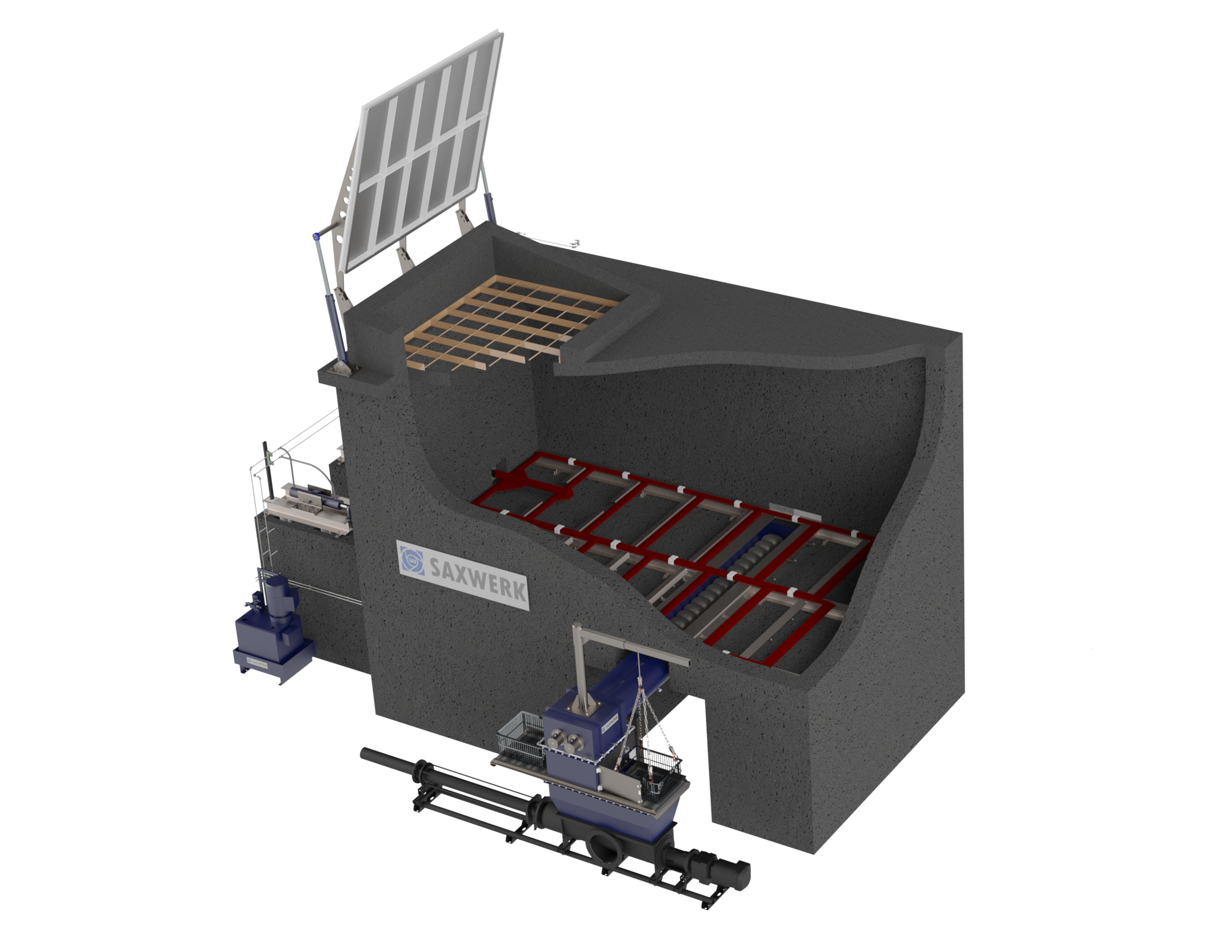

Discharge Separator

Foreign sludge reception with integrated separation of foreign particles.

Description

External sludge is often contaminated with foreign particles and is the cause for

damage of downstream plant components.

The SAXWERK discharge separator prevents damage caused by foreign matter and increases the availability of the entire plant.

Function

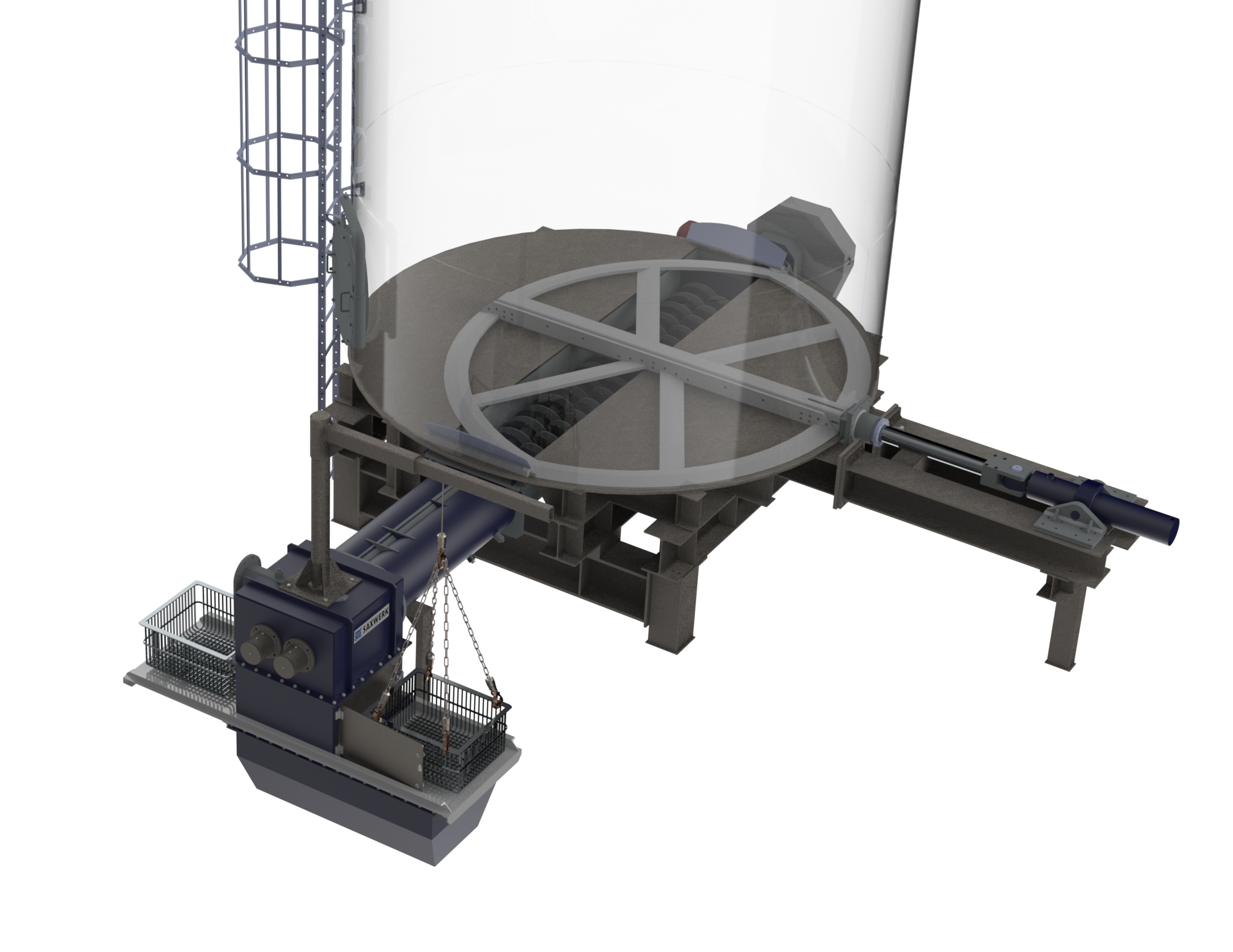

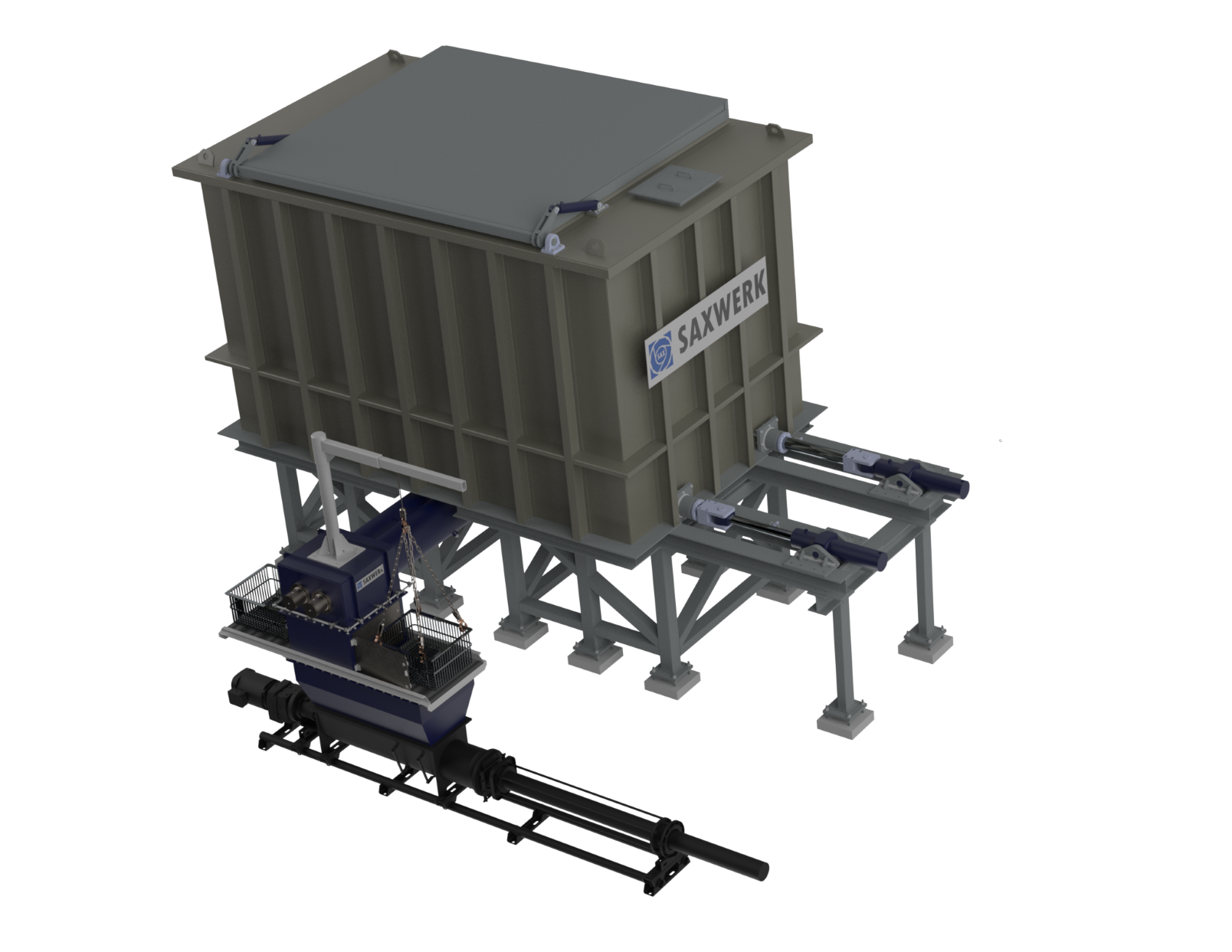

The sewage sludge is conveyed from the inlet opening in the bottom of the

bunker through the integrated foreign particle separator by means of pressure screws. Foreign particles are collected in a screen cassette.

Foreign particle removal:

The conveying pressure is monitored by a sensor. When the pressure rises to approx. 2 bar, the screw is switched off and the foreign particals can be removed.

A timed rinsing process (duration approx. 10-30 sec.) is automatically initiated for this purpose. The rinsing water will be removed by the downstream conveyor (pump).

The flushed screen cassette can be removed with the foreign particles.

Duration of the cassette change approx. 1 – 2 minutes.

The downstream conveyors remain in operation during the cassette change.