Bioenergy Plants

Benefits:

Bioenergy plants up to 3 MW

In cooperation with our partners in Estonia Rapla Metall OÜ, Saxwerk can also offer small bioenergy plants from 1 MW up to about 3 MW. The plants are mostly completed in the workshop, which means that the total cost can be kept down.

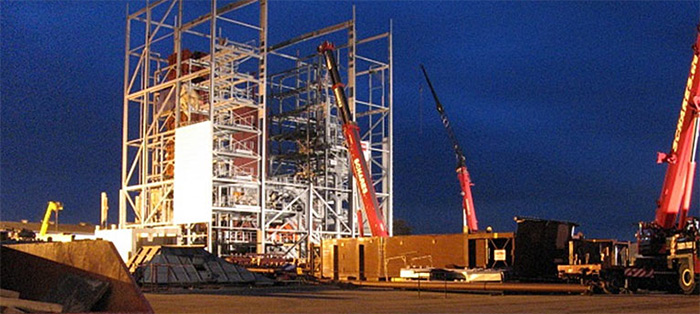

CHP plants

Saxwerk is a representative for Kablitz. Kablitz has many years of experience in CHP plants around the world, with a wide range of different fuels.

For smaller installations, ORC technology can also be used, from thermal oil produces electricity and hot water in a standard module.

For more information about Kablitz: www.kablitz.com.

Hot Gas Plants

For board and pellets industry, it normally requires that the combustion unit provide the dryer and the boiler with energy. Saxwerk has long experience in the type of process solution, with drying units and boilers connected to the same combustion unit.

Power Plant Boilers