Saxwerk – from silo engineering to complete delivery

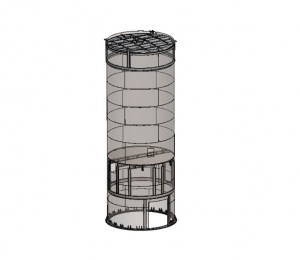

Silo storage, round or rectangular, prepared for the installation of Saxwerk discharge systems

Saxwerk uses state-of-the-art 3D CAD applications to create highly detailed models. You can conveniently integrate these into your overall planning. This gives you a comfortable planning reliability for your plant.

Variant 1.

Silo Basic Engineering

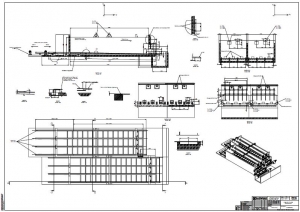

Many of our customers and plant operators have their own drawing departments or service providers. Here, the Basic Engineering Package is often chosen. You receive all relevant data from us on clear 2D drawings, as well as a 3D stepfile for your planning. With this material, you can create production drawings and structural analyses yourself or have them created.

Variant 2.

Silo Advanced Engineering for on-site production

Here Saxwerk provides you with a complete set of workshop drawings with parts lists as well as verifiable structural analysis. With this engineering package, you can directly request the construction of your silos from steel construction companies in your area.

We also can offer you assembly or assembly supervision.

Bolted silos

Element-Tec® silos are made of sheet steel. The elements are prefabricated and coated at the factory. The elements can be stacked excellently with a correspondingly low transport volume.

The silo is assembled on site in the simplest and most

time-saving way by screwing the individual elements together. Welding work is not necessary.

Roof: The roof is supplied in several parts with inlet, manhole,

edge railings and the necessary connecting pieces.

Jacket: The silo size determines the number of jacket segments. All accessories are already fitted at the factory.

assembled at the factory.

Discharge systems and base plate: The silo floor is designed as a flat floor and

The silo floor is designed as a flat floor and adapted for SAXWERK discharge systems.

Two standard designs, type M and P, are available.

available. In the case of the standing frame version, type M

the shell elements are supported on the base plate.

Type P is supplied with a substructure of steel supports.