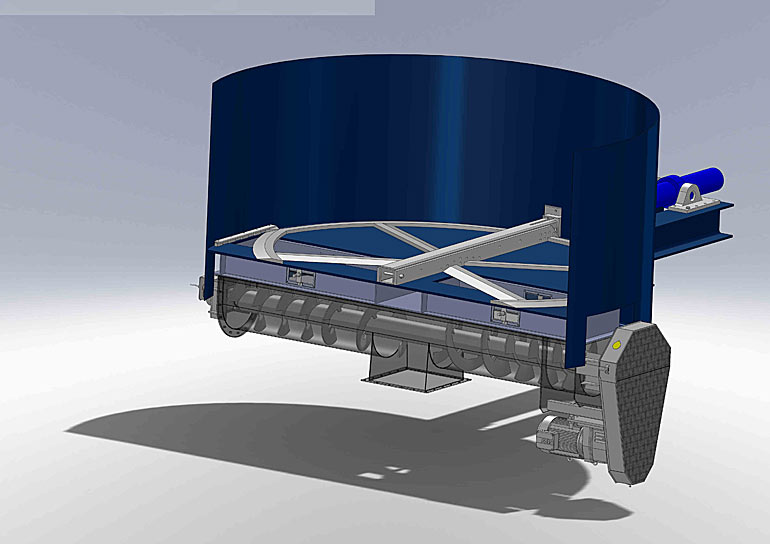

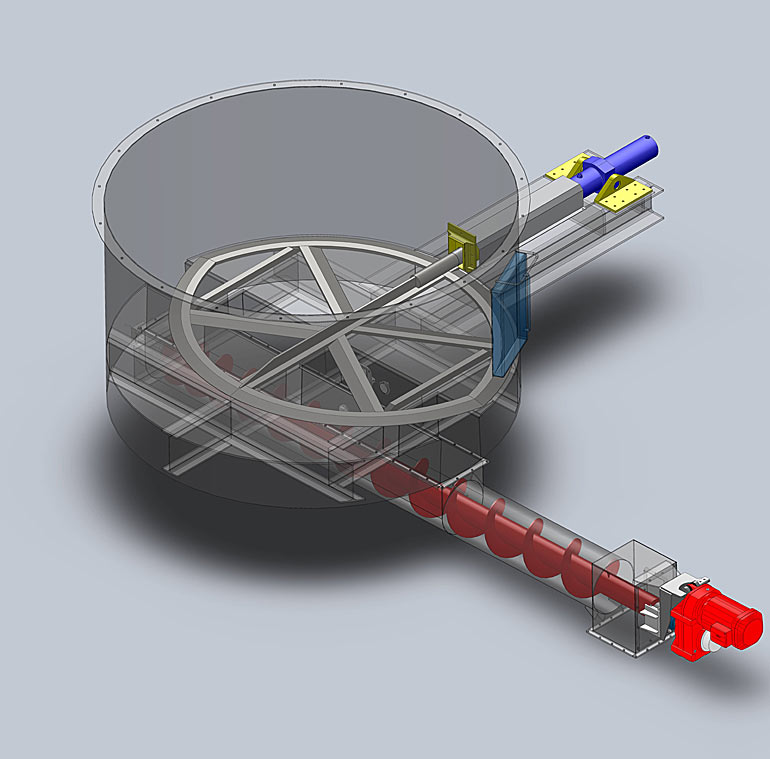

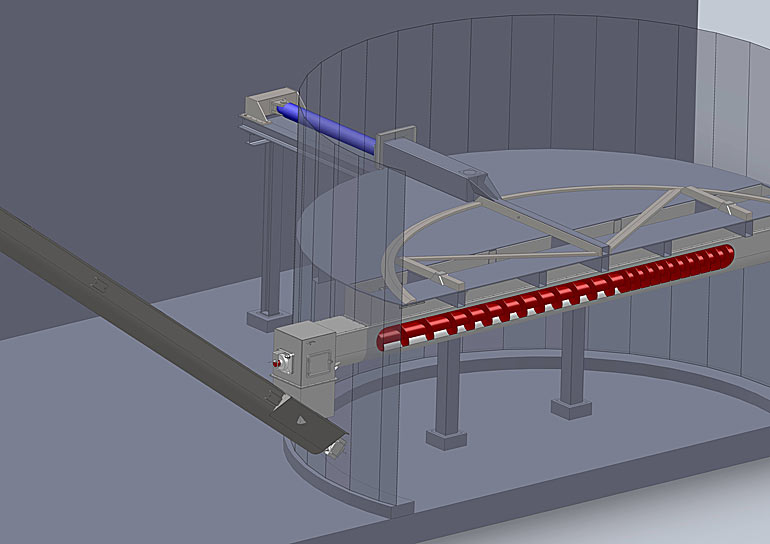

Sliding frames

Application

Saxwerk original sliding frame is available in three standards.

- Wood and other bulk materials.

- Sludge (municipal, fiber and bio-sludge)

- Ashes

In addition to these custom sliding frames, we have special designs for all types of materials and diameters.

Function

Sliding frame work all over the silo bottom.

With one or more discharge screws in silo bottom, from wall to wall, the self-collapsing effect is used. The silo discharge has no other moving parts than the forward and backward moving sliding frame, therefore there is no direct wear on machine parts that can come loose and damage the following machines.

Thanks to the accessibility from the outside, maintenance work such as replacing seals in hydraulic cylinder, can be performed even when the silo is completely filled.

Design possibilities

Saxwerk original sliding frame can be built into the silo diameter from 2000 to 10 000 mm. The sliding frame can also be adapted to various diameters for installation in existing silos. This, for example to overcome the existing problems such as the bridge problem in silos. The silos can be made of steel, concrete or plastic.