Rotary Feeders

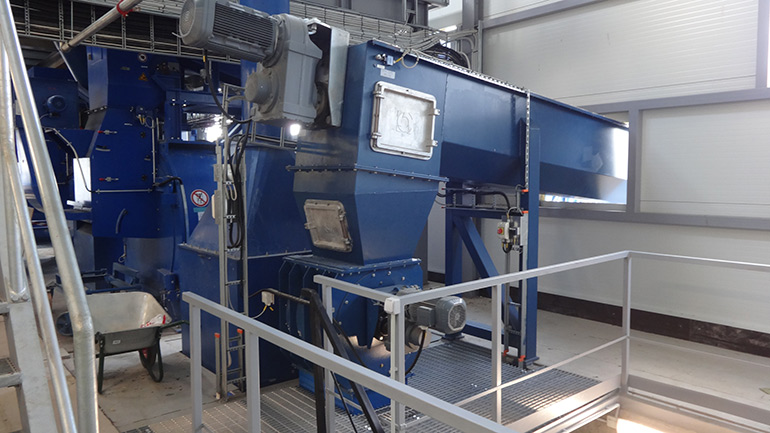

Application

We deliver Rotary feeder for the cellulose and wood processing industry, chemical industry, dust and ash handling etc.

Function

The Rotary feeder is suitable for:

- Separate different pressure conditions

- Pneumatic transport

- Fire Protection

Design possibilities

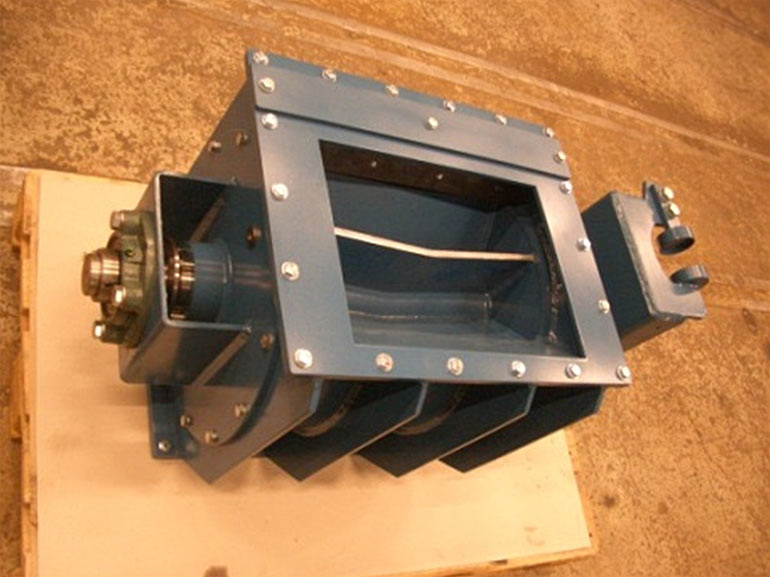

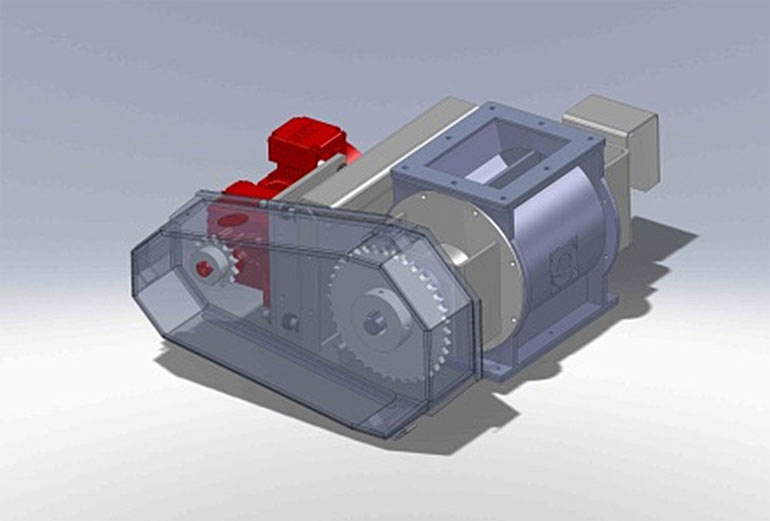

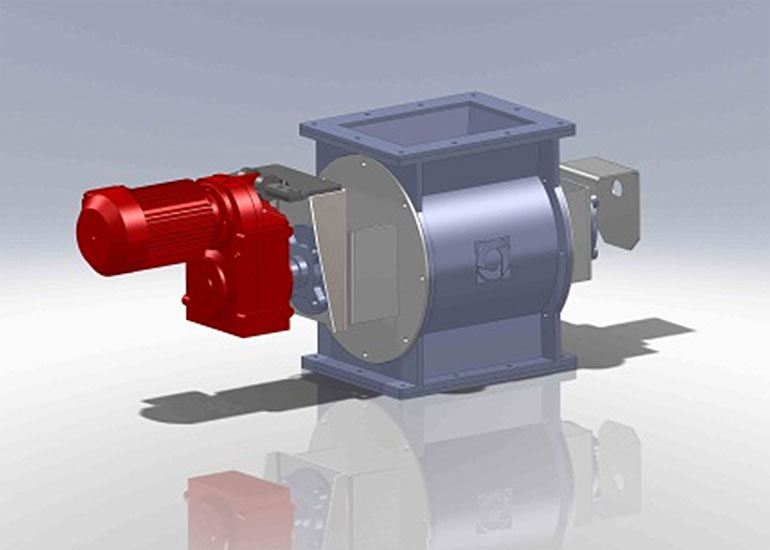

The Rotary feeder is available in three main designs:

- Standard rotary feeder.

- Heavy duty design

- Stainless steel

All rotary feeders can be supplied with extended bearing. Drive can be chain type or direct type.

| Type: | Capacity (m3/h): | Height (mm): | Inlet (mm): | Outlet (mm): |

|---|---|---|---|---|

| RF 5 | 5 m3/h | 300 | 200×150 | 250×150 |

| RF 10 | 10 m3/h | 425 | 285×200 | 285×200 |

| RF 15 | 15 m3/h | 372 | 372×250 | 372×262 |

| RF 35 | 35 m3/h | 500 | 400×300 | 500×300 |

| RF 50 | 50 m3/h | 600 | 452×325 | 512×372 |

| RF 75 | 75 m3/h | 600 | 452×325 | 512×372 |

| RF 100 | 100 m3/h | 850 | 452×456 | 512×512 |

| RF 150 | 150 m3/h | 850 | 652×456 | 712×512 |

| RF 250 | 250 m3/h | 1150 | 652×628 | 712×724 |

| RF 350 | 350 m3/h | 1150 | 952×628 | 1012×724 |

| RF 500 | 500 m3/h | 1380 | 794×754 | 894×868 |

| RF 700 | 700 m3/h | 1380 | 1184×754 | 1284×868 |

Saxwerk conducts continuous product development. We reserve the right to make changes.