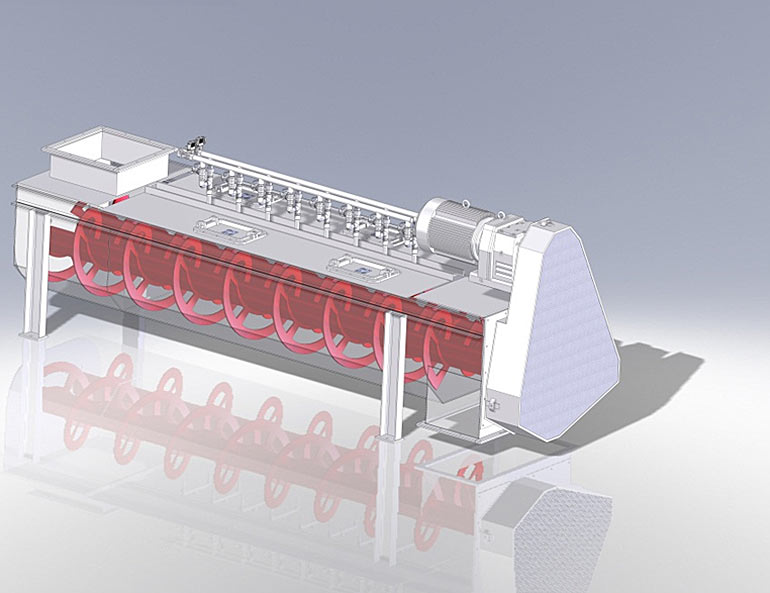

Ash Conditioning

Function

The dry ash must be feed in event flow to the conditioner. After the Ash conditioner the ash has a moisture content of approximately 20 – 25%. The humidified ash can be fed to a container or directly to a truck.

For humidification water is used. The water consumption varies depending of ash type.

Consumption

Approximately 100 l / min. for mixture of 13 m3 ash/h

Approximately 200 l / min. for mixture of 25 m3 ash/h

| Type: | Capacity: | Width x Height x Length: |

|---|---|---|

| AC 220 | 3 m3/h | 520 x 505 x 1590 mm |

| AC 315 | 13 m3/h | 676 x 656 x 2450 mm |

| AC 400 | 25 m3/h | 832 x 718 x 2850 mm |

| AC 500 | 50 m3/h | 1010 x 1078 x 4000 mm |

| AC 550 | 75 m3/h | 1108 x 1080 x 4900 mm |

| AC 630 | 100 m3/h | 1320 x 1260 x 6450 mm |